Fiber Optics Condition Monitoring

Fiber Optics Condition Monitoring

Compared to conventional mechanical or electrical sensing system, fiber optic sensing system has the following advantages:

BOTDR Optical fiber strain distribution measuring system

Fiber Optics Condition Monitoring uses an optical fiber distributed sensing system for monitoring. It offers a high accuracy of 25 micro strains and spatial resolution of 10 cm for monitoring. It can precisely measure strain/temperature distribution, therefore predicts failures on oil wells, power plants, civil engineering structure, etc. The Fiber Optics Condition Monitoring also predicts failures by detecting the abnormal change of strains or temperature.

Features

Features

Long-gauge Optical fiber strain distribution measuring system

Construction materials and concrete in particular, can be affected by local discontinuous defects, such as cracks, air pockets and inclusions. Therefore for structural monitoring purposed it is necessary to use the gauge length deformation sensors which are insensitive to material discontinuities at the micro- and meso-levels.

Compared to conventional mechanical or electrical sensing system, fiber optic sensing system has the following advantages:

- Immune to EM, mechanical vibrations, climatic stress, humidity, corrosion, radio, frequency, and microwave

- Non-conductivity

- Small size

- Light weight

- Fast response

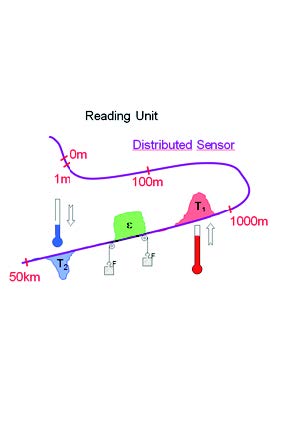

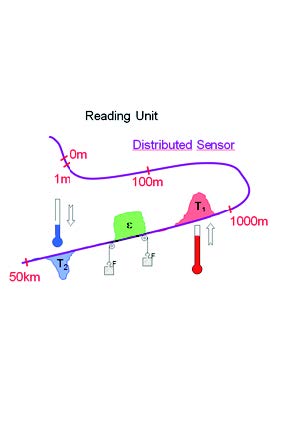

BOTDR Optical fiber strain distribution measuring system

Fiber Optics Condition Monitoring uses an optical fiber distributed sensing system for monitoring. It offers a high accuracy of 25 micro strains and spatial resolution of 10 cm for monitoring. It can precisely measure strain/temperature distribution, therefore predicts failures on oil wells, power plants, civil engineering structure, etc. The Fiber Optics Condition Monitoring also predicts failures by detecting the abnormal change of strains or temperature.

- Use standard single mode telecom fibers for real time simultaneous measurement of strain and temperature

- High spatial, strain, and temperature resolution and accuracy

- Measurements can be made over the entire length of fiber, up to 100km in length

Long-gauge Optical fiber strain distribution measuring system

Construction materials and concrete in particular, can be affected by local discontinuous defects, such as cracks, air pockets and inclusions. Therefore for structural monitoring purposed it is necessary to use the gauge length deformation sensors which are insensitive to material discontinuities at the micro- and meso-levels.

|

|

|

|